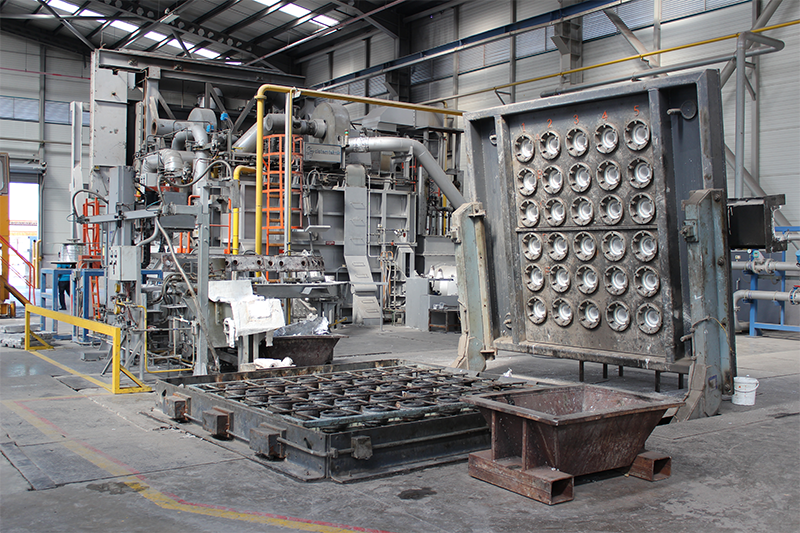

Our aluminium billet production facility, which was included in our organization in 2011, produces 45.000 tons of billets annually. The foundry has a melting furnace, homogenization furnace and cooling cabinets. It has a closed area of 2.500 m² and crane use is available throughout.

In the process stage, operations are carried out automatically with the state-of-the-art Homogenization furnace and cooling cabinet feeding and discharging charging car. The process in the foundry continues as melting, alloying, degassing, filtration, casting, cut-to-length, homogenization, cooling and packaging, respectively.

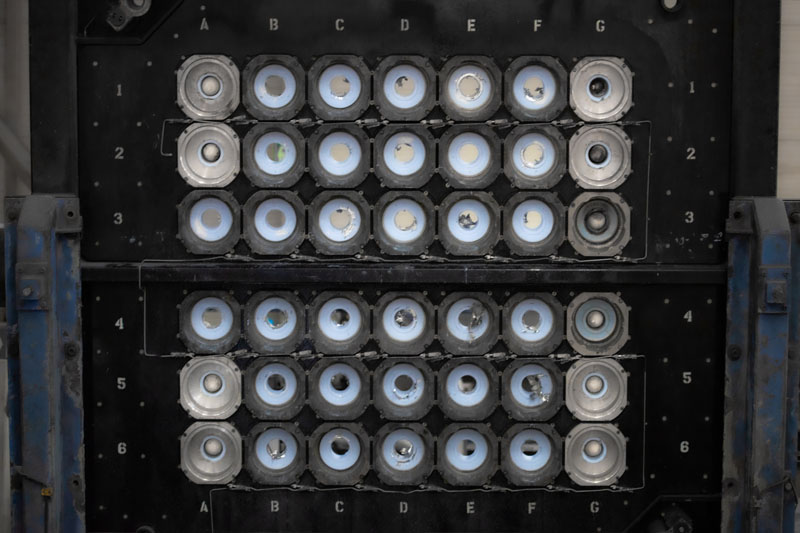

Billets produced in our foundry have a diameter of 127”, 152”, 178”, 203” and a length of 6.500 mm, and besides standard alloys (1050, 1070, 6060, 6063, 6463, 6005, and 6082), desired alloys can be produced.

In order to obtain the desired quality in our billets, spectral analyzes and controls are performed in the spectrometer device by taking samples from the molten metal during alloying before casting and from the billet after casting.

After homogenization; shell thickness measurement, microstructure control, segregation and grain boundary analysis are performed.