Extrusion is the process of obtaining the profile that has the shape of the mold by passing the aluminium billet through steel molds with the great force provided by the press.

Aluminium extrusion is done hot. Billets are heated at 420-520°C, molds should be heated to 450°C and the temperature of the profile coming out of the press is over 500°C. The profile coming out of the extrusion is cooled; cold stretching is applied and cut to the desired length. Then, the profiles are strengthened by applying heat treatment. During this process, the profiles are kept at 185°C for 5 hours.

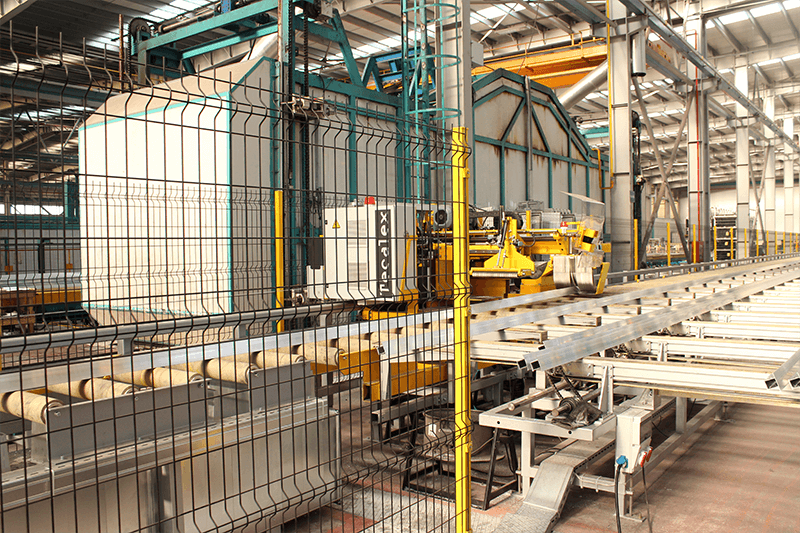

In our factory, we meet the demands of profile production in different sizes with our presses of 8 different strengths and sizes that vary between 6-7-8-10 inch. Our factory, which has a production capacity of 70.000 tons per year, can produce special alloys such as EN AW 6082 as well as EN AW 1050, 1070, 6060, 6063, 6463-6005 alloys.

Production of aluminium profiles for a wide range of products for various sectors and purposes are carried out in our extrusion lines.